Maxon News

HomeMaxon News

News

KERN & MAXON Join Forces for the North American Market

Maxon is proud to support KERN's expansion into the U.S. market by leveraging its well-established North American sales, distribution, and service network.

Read more KERN & MAXON Join Forces for the North American Market

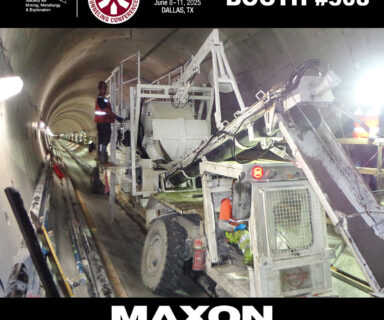

Maxon Booth #308 at RETC June 8-11, 2025

Visit the Maxon Underground Team Booth #308 at the RETC Conference on June 8-11, 2025

Read more Maxon Booth #308 at RETC June 8-11, 2025

Mobile Conveying Services Authorized Dealer of Australia & New Zealand

Maxon Industries, Inc. is pleased to announce Mobile Conveying Services as an authorized dealer for Maxon material handling equipment for the construction industry in Australia and New Zealand.

Read more Mobile Conveying Services Authorized Dealer of Australia & New Zealand

Maxon Units Available for Rent!

Have a short term project? Looking to rent? Rent a Maxon Agitor, Maxcrete, Mobile Maxcrete, Surgecrete, or any of our other equipment!

Read more Maxon Units Available for Rent!

Maxon Agitors and Surgecrete Head to the UP!

Maxon shipped 6 truck mounted insulated 12yd Agitors and a Surgecrete up to the UP - Upper Michigan for the Kokosing Alberici Traylor JV!

Read more Maxon Agitors and Surgecrete Head to the UP!

Rail Mounted Mobile Maxcrete Used for REM Light Rail

Railworks and NouvLR utilized a self-propelled Maxon Mobile Maxcrete mounted on rail wheels during final installation and concrete placing on the REM Light Rail project in Montreal, Canada.

Read more Rail Mounted Mobile Maxcrete Used for REM Light Rail

NAT 2024 JUNE 23-26, 2024

The Maxon Underground Team will be attending the 2024 North American Tunneling Conference June 23-26, 2024 in Nashville, TN.

Read more NAT 2024 JUNE 23-26, 2024

Maxon 6yd Maxcrete on Morooka Track Carriers for Remote Concrete Delivery!

Maxon 6yd Maxcrete mounted on a Morooka MST3000VD track carrier!

Read more Maxon 6yd Maxcrete on Morooka Track Carriers for Remote Concrete Delivery!

Maxcrete Remixes Concrete for Chicago Harbor Lock & Dam

JF Brennan used a Maxon Maxcrete to remix their concrete mix and Superplasticizer before placing it on the Chicago Harbor Lock floor 28feet below the water surface.

Read more Maxcrete Remixes Concrete for Chicago Harbor Lock & Dam

Factory Refurbished Truck Mounted 12 yd Agitors For Sale – SOLD!

Maxon currently has (4) Factory Refurbished Truck Mounted 12 yd Agitors For Sale! For more information check out our Shop or Contact Us!

Read more Factory Refurbished Truck Mounted 12 yd Agitors For Sale – SOLD!

Load more

Something went wrong, please try again later or contact the site administrator

Categories

- Agimax

- Agitor

- Concrete Paving

- Dams and Civil

- Environmental Solidification

- Event

- Marine and Offshore

- Maxcrete

- MinI Maxcrete

- Mobile Agitor

- Mobile Maxcrete

- Neva-Shock

- Paste Backfill

- Prestress and Precast

- Remote Concrete Delivery

- Surgecrete

- Track-Mounted Equipment

- Transmixer

- TranzLoader

- Travel Mixer

- Tunneling Mining and Shotcrete

- Uncategorized

- Underground

- Underground

Recent posts

-

Maxon Booth #308 at RETC June 8-11, 2025May 20, 2025

-

Maxon Units Available for Rent!August 7, 2024

-

Maxon Agitors and Surgecrete Head to the UP!July 27, 2024