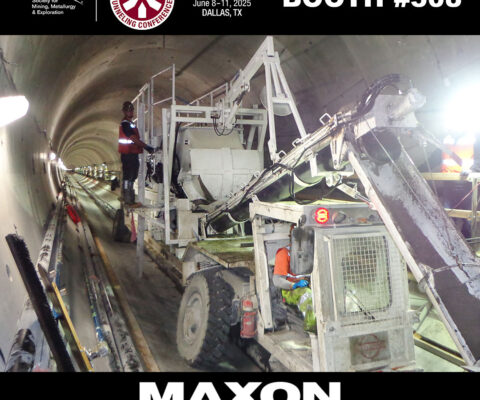

Twin Shaft Maxcrete

DETAILS

The Maxon Twin Shaft Maxcrete adapts Maxon industry leading agitated hopper design for environmental waste contractors looking for additional shear action in a paddle mixer/pugmill. Units are available in capacities from 12 to 20 yd3 (9 to 15 m3). The two bi-rotational agitator shafts are independently driven and controlled, allowing contractors to change shaft speed or direction to increase material exchange in the turbulent area where the two mixing zones intersect. The Twin Shaft Maxcrete can be utilized in either continuous or batch format.

As with all Maxcretes, the Twin Shaft Maxcrete includes either steel grid or hinged solid covers for easy loading and visual inspection. Units are available with electric or diesel power for remote applications, and a variety of discharge gates, screw augers and/or conveyors to assist with material handling.

Key Features

- Bi-rotational twin shaft paddle agitators ensure thorough mixing

- All hydraulic drive, with 121:1 heavy duty direct drive gear reducers

- Open top for easy loading

- Handles most solids or liquids

- Two hydraulic vibrators to assist in clean out

- Turnkey engineered solutions including pumps, conveyors, and silos

Technical Specifications

CAPACITY

12 to 20 yd3 (9 to 15 m3 )

EMPTY WEIGHT

16,000 lbs (7257kg) *

LENGTH

314” (7976 mm) *

WIDTH

98” (2489 mm) *

HEIGHT

84” (2134 mm) *

* Note: 20 yd3 skid mounted unit

Options

- Skid or trailer mounted

- Charge and discharge belt conveyors

- Elevated operator platform

- Hinged grid or solid steel covers

- Knife gates to feed multiple hoppers, buckets or conveyors

- Spray bar for addition of liquid material

Maxon Twin Shaft Maxcrete

The two bi-rotational agitator shafts are independently driven and controlled, allowing contractors to change shaft speed or direction to increase material exchange in the turbulent area where the two mixing zones intersect.