Trio of Surgecretes Utilized in the Repair of Tampa Bay Reservoir

Trio of Surgecretes Utilized in the Repair of Tampa Bay Reservoir

Kiewit C.W. Bill Young Reservoir

CONTRACTOR

LOCATION

Tampa Bay, Florida

APPLICATION

SHARE:

OVERVIEW

The C.W. Bill Young Regional Reservoir in Tampa, Florida first began operating in 2005. At 15.5 billion gallons the reservoir serves as an above-ground storage facility during the wet season. During the dry months, the reservoir is drawn down. Water is then sent to the regional treatment plant and distributed to 2.3 million people served by Tampa Bay Water. Soon after being constructed, large cracks (see below left) began to form in the facility’s soil cement erosion control lining, eventually forming in over 70 percent of the interior face.

After extensive studies and numerous lawsuits it was determined that the old system had failed to allow water to drain from the soil wedge between the flat plate soil cement layer and the PVC membrane. When the reservoir was lowered the water in the soil wedge created a pressure difference between the layers and large cracks formed in the soil cement. Tampa Bay Water awarded a $129 million contract to Kiewit Infrastructure South Co to remove the existing liner, and install a new geomembrane, better engineered drainage system, and thicker soil cement.

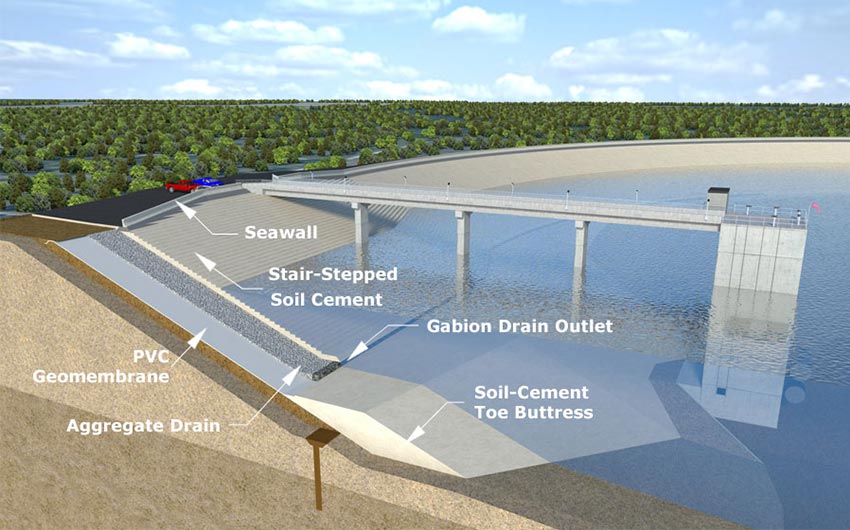

Drawing depicts the cross section of Kiewit’s newly designed Reservoir walls. Kiewit’s design includes new aggregate drainage layer that will alleviate the pressure the caused the cracks in the old Soil cement layer. Three Maxon Surgecretes were instrumental in rapid delivery of aggregate and stair stepped soil cement layers around the 5 mile perimeter of the Reservoir.

Kiewit turned to Maxon Industries of Milwaukee, Wisconsin and RCC Conveyors (RCCC) of Volo, Illinois to provide an engineered system of equipment to assist in placing the new aggregate drainage system and the 700,000 cubic yards of soil cement that make up the new interior face of the reservoir. Maxon and RCCC supplied a specialized trailer mounted delivery system with a 15 cubic yard Maxon Surgecrete being towed by a 150’ Crawler Placer conveyor system. In addition, Maxon custom built two Surgecrete hoppers mounted to two Gomaco 9500 placers to assist in placing the soil cement in the lower 25’ of the reservoir walls.

The Delivery System

Kiewit, in collaboration with Maxon and RCCC, selected equipment that could not only rapidly place the new aggregate drainage layer, but also the stair-stepped soil cement layer. With goals of placing as much as 3,000 to 5,000 cubic yards of material per day, Kiewit needed units that had a large surge capacity to keep up with the soil cement production from the pugmills while continuously placing the material on the sloped walls.

The Surgecretes

To place aggregate and soil cement on the high walls, Kiewit selected a RCCC Crawler Placer CP150 with a 150” triple telescoping boom towing a 15 cubic yard Maxon Surgecrete on a trailer around the inside perimeter of the reservoir. The trailer (from a previous Kiewit project) provided a perfect mobile platform on which to place the Surgecrete. The Surgecrete would then utilize its 36” x 25’ conveyor to feed the Crawler Placer’s 24” belt.

36″ belt on the Surgecrete keeps production at rates of over 3,000 cubic yards

To place soil cement for the lower steps of the walls, Kiewit used two modified Gomaco 9500 placers. The existing hopper on the 9500’s included a 12″ screw designed to handle concrete. In initial trials with the 9500 placers the soil cement material would bridge in the hopper, slowing production.

In short order, Maxon engineered and delivered two custom low profile Surgecrete hoppers to replace the existing 9500 hoppers. These 12 cubic yard Surgecretes utilized Maxon’s standard 24″ diameter screw that provided a jam free solution for the 9500 placers. “We have not seen the bridging and repetitive stops (that we saw previously)”, remarked Randall Starkey, equipment superintendent for Kiewit.

To reach the ambition placing rates the system needed to be able to keep pace with the twin soil cement pugmills. A continuous stream of 24 yard Cat Ejecto Bodies ran soil cement to the placing trailer (see page 4 for details on aggregate placement with the system). The Ejecto bodies discharged into an 8 yard Cat front end loader that then dumped the soil cement into the Maxon Surgecrete. Kiewit estimated that the Maxon Surgecrete and the RCCC CP150 will place and travel nearly 500 miles before the project is complete.

To feed soil cement to the Maxon Surgecrete hopper on the 9500’s, Cat dump trucks with Ejecto bodies backed slowly into place in front of Surgecrete hopper and the truck was placed in neutral. The Surgecrete Hopper on the 9500 was equipped with two push rods that allowed the 9500 to push the dump trucks while simultaneously placing soil cement to the lower portion of the stair-stepped walls. Once the Ejecto bodies on the dump truck were empty, the driver placed the truck back in drive and departed. At the end of each shift, the hydraulically operated door on the Surgecrete tailgate raised to assist in final clean-out of the hopper.

Kiewit had a very tight placing window (maximum 90 minutes allowed from pug-mill to placement to maintain proper moisture in the soil cement) the system needed to run extremely efficiently. When there would be lags from one truck to the next, the Surgecrete ensured a continuous stream of materials to the placer.

CAT Ejecto Body to Surgecrete Hopper to Gomaco 9500

Aggregate Placing

Prior to placing the soil cement, Kiewit placed the aggregate/drainage layer on top of the new geomembrane. During warm days when the soil cement operation were idle, Kiewit utilized RCCC’s Crawler Placer to place aggregate in the upper regions of the walls from down on the Reservoir floor.