applications

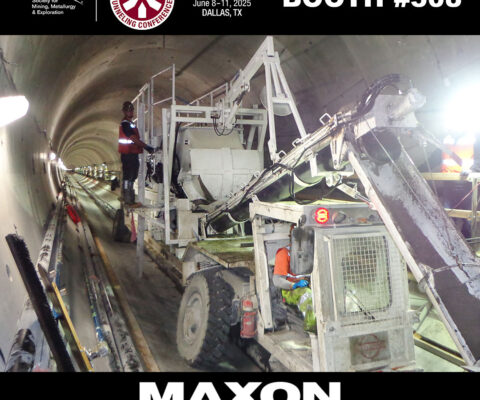

From the mass transit tunnels of New York City and Los Angeles to the sub-surface mines of Africa, the experts at Maxon have assisted a full range of tunnel and mine projects worldwide. Maxon provides complete equipment solutions including skid, rail and rubber tired equipment for placing structural concrete, grout, shotcrete and foamed concrete. Maxon’s breadth of knowledge includes small and large bore tunnels, slip formed inverts, segmental section tunnels, cast in place (in-situ) lining and sprayed shotcrete. Tunneling and Mining contractors turn to Maxon for hauling and placing ground support materials in rail car mounted or rubber tired vehicles/mine chassis as well as material handling equipment (belt conveyors and screw augers).

Large Bore Lining

When pouring full round large bore tunnels, over 20’ (14m) in diameter, contractors rely on Maxon engineered solutions including transporters and remix surge hoppers.

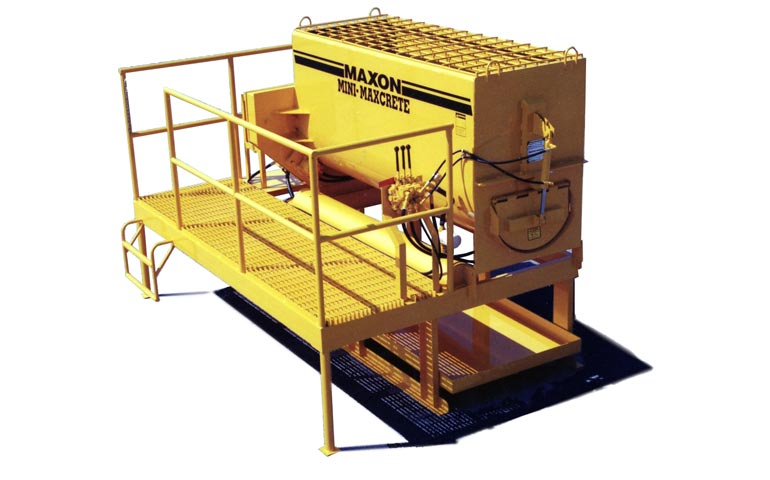

Small Bore Lining

Maxon has developed a comprehensive line of concrete transportation and placement equipment for small bore applications under 16’ (5m) in diameter.

Invert & Sidewalk

For placement of tunnel invert or sidewalks for mass transit tunnels, Maxon offers the Mobile Maxcrete. Units are highly adaptable to various undergrounds applications with either canted (buffed) tires for driving on the curved precast tunnel surface or solid rubber tire for driving on the flat paved invert.

Mining & Shotcrete

Placement of ground support within excavated mine caverns requires a compact unit designed to handle the rigors of underground applications. Maxon offers solution to contractors looking for either open top haul bodies (Maxon Maxcretes) or conventional drum mixers (Maxon Transmixers) in sizes from 2 yd3 (1m3) to 10 yd3 (7m3).