Truck Mounted Maxcretes and Mobile Maxcrete Build Channel for Chilean Mine

Truck Mounted Maxcretes and Mobile Maxcrete Build Channel for Chilean Mine

I.C. Vicente Codelco Chile Copper Mine Channel

Truck-Mounted Maxon Maxcrete transporter (left) feeds Maxon Mobile Maxcrete (center) which then feeds the Power Curbers Slipform (right). Narrow pathways and height restrictions mandated the use of low profi le Maxon equipment.

CONTRACTOR

I.C.Vicente

LOCATION

Santiago, Chile

APPLICATION

EQUIPMENT

SHARE:

OVERVIEW

Chilean Contractor Ingenieria Civil Vicente S.A. (ICV) is building a channel (sluice) to carry crushed copper ore from inside the mountain to a smelter in the valley. The crushed ore will be mixed with water and put in the concrete channel (80 kilometers long at a 1% grade) to fl ow to the smelter by gravity.

The channel at Codelco’s Minera Andina Mine is located near Los Andes in the Acongaqua Valley, an area principally known for its wineproducing vineyards. The mine is also 20 miles from a popular ski resort in the Andes Mountains and 100 miles from Santiago, Chile.

THE CHALLENGE

The channel, which is 1.3 meters high by 1.3 meters wide, had been partially hand built with forms by other contractors. However, the process was very slow and the concrete was difficult to deliver to the forms because the channel went inside the mountain and through various tunnels of limited space.

Power Curbers of Salisbury, NC along with ICV, developed a research project to test whether they could slip-form the concrete channel with equipment used for barrier walls. Initial tests were successful with the slip-form paver, except for delivering concrete to the site and feeding the paver in confined spaces.

THE RESULT

ICV turned to Maxon Industries to design a specialized delivery system to consistently supply concrete to the Power Curber 8700 Slip-form Paver. Maxon proposed a new Mobile Maxcrete and truck-mounted Maxcretes. The Mobile Maxcrete has the unique ability to receive concrete quickly from a concrete truck, remix or re-temper the concrete if required, and slowly feed the concrete to the slip-form paver in a continuous manner, all while maintaining a low profile. The Mobile Maxcrete’s 10 cubic yard (7.65 cubic meter) surge capacity allows the haul truck to quickly discharge while the Mobile Maxcrete continuously feeds the slip-form paver.

Due to the confined space in the tunnel, special Maxon concrete carriers were mounted on the customer’s Mack trucks to discharge the concrete into the Mobile Maxcrete quickly while operating in the tunnel’s confines.

Truck-mounted Maxcrete transporter feeds concrete

The Concrete Channel

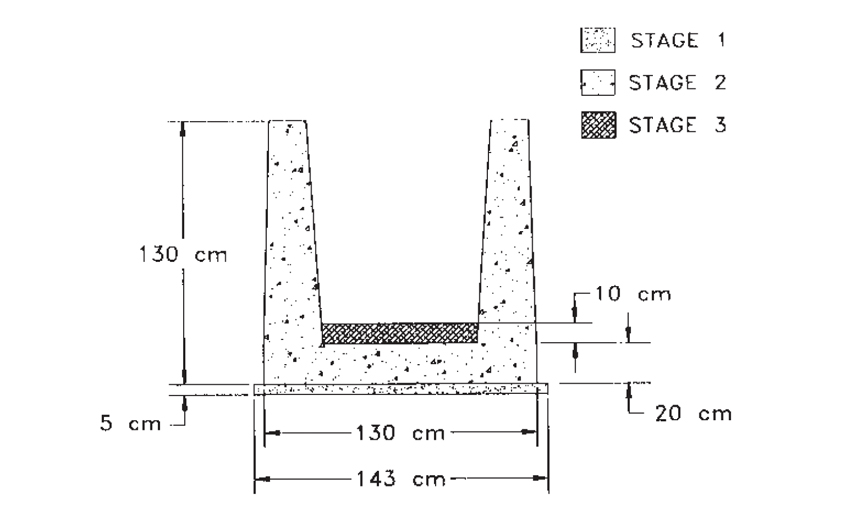

The channel is slip formed in three separate stages:

Stage 1

The concrete base is laid 5 cm high by 143 cm wide.

Stage 2

Using the same machine with a different mold, the sides of the channel are formed at 1.30 meters high by 1.33 meters wide using .8 cubic meters of concrete per linear meter of channel paved.

Stage 3

A special mix of extremely hard aggregates and a high ratio of cement is used for the bottom liner of the channel. The liner is 10 cm high by 75 cm wide. The liner is critical because the copper ore is extremely abrasive.

The Game Plan

With the near vertical walls of the channel, the mix design of the concrete has to be exactly controlled and the slump of the concrete cannot vary more than 2 cm. The contractor’s target slump is 4 to 5 cm. The harsh mix with 38 mm maximum size aggregate can be compared to slip-form concrete supplied for airport pavement.

ICV is familiar with slip-form paving, having the first CMI slip-form paver and Hagan Central Mix Plant in Chile. The channel is being paved in three separate passes. The first pass lays the concrete base which is 5 cm high by 143 cm wide. The second pass uses the same machine with a different mold, slip-forming the channel to 1.30 meters high by 1.33 meters wide, using 0.8 cubic meters of concrete per linear meter of channel paved. The third pass has a special concrete mix using extremely hard aggregates and a high ratio of cement as a bottom liner for the channel. The liner is slip-formed 10 cm high by 75 cm wide inside the channel itself.

THE EQUIPMENT

Truck-Mounted Maxcretes

Maxon supplied six (6) low profile 8 cubic yard (6.12 cubic meter) Maxcrete haul bodies mounted on Vicente’s Mack trucks. The units have special full sweep agitators to permit complete discharge of the concrete without hoisting the body. High torque heavy duty Agitator Drives are used so the agitator can turn in extremely harsh and low slump concrete. The truck-mounted units discharge into a newly designed Mobile Maxcrete.

Mobile Maxcrete remix surge hopper which feeds concrete…

…to the Power Curber 8700 Slipform Paver forming the channel

The Mobile Maxcrete

The Mobile Maxcrete can quickly receive concrete from the truck-mounted Maxcrete haul bodies, re-temper or remix the concrete if needed, and, under exacting control, slowly discharge the concrete onto a belt conveyor which feeds the Power Curber slip-form unit. The discharge belt conveyor has a radial stacking design which can raise and lower the conveyor, control discharge speed, and swing the conveyor in either direction.

The open-topped 8 cubic yard (6.12 cubic meter) truck-mounted Maxcretes load quickly from the Hagan Central Mix Plant. As soon as a truck-mounted Maxcrete arrives at the paving site, the driver positions the truck to discharge onto the Mobile Maxcrete’s charge belt conveyor and places the truck in neutral. The Mobile Maxcrete, equipped with a pusher frame, then pushes the truck-mounted Maxcrete as it proceeds. This allows the Mobile Maxcrete operator to match his speed to that of the slip-form paver while simultaneously pushing the truck-mounted Maxcrete. The truck-mounted Maxcrete discharges quickly into the Mobile Maxcrete and departs for the plant for another load.

Front view showing the steel rebar as the slipform pours concrete into the channel forms

The Maxon equipment was delivered to Chile in early 1997. The biggest challenge initially was timing the simultaneous dumping of the truck-mounted units, remixing the concrete in the Mobile Maxcrete, and properly feeding the slip-form paver at the correct speed.

However, ICV is now able to place over 1,600 linear feet of concrete per day, an 800% improvement from the 197 linear feet per day formed by the previous contractor

Since the surrounding mountains are rich in copper deposits, other mines may adopt this method of moving ore from the mountain to the smelter. ICV hopes that their success will result in additional contracts at various Chilean mines for many years to come.