I.C. Vicente Codelco Chile Copper Mine Channel

Truck Mounted Maxcretes and Mobile Maxcrete Build Channel for Chilean Mine

Truck Mounted Maxcretes and Mobile Maxcrete Build Channel for Chilean Mine

I.C. Vicente Codelco Chile Copper Mine Channel

CONTRACTOR

LOCATION

Codelco’s Minera Andina Mine

Los Andes, Aconcagua Valley, Chile

APPLICATION

EQUIPMENT

SHARE:

PROJECT OVERVIEW

Redland Genstar, Inc. in Baltimore, Maryland purchased a New Maxon Maxcrete for use in processing mine tailings from a sediment pond. The process included the excavation, mixing and pumping of the material into an abandoned underground mine located adjacent to the sediment pond

THE PROCESS

The Pond Sediments

- 65% calcium carbonate

- 10% magnesium carbonate and

- 25% various acid insoluble materials (including iron pyrite, clays and chalcopyrite)

Particle size was generalized as 100% passing 30 mesh and 70% passing 325 mesh, but there were considerable extraneous materials ranging from sticks, roots, tree stumps and other foreign objects disposed of in the pond over its 60 year life.

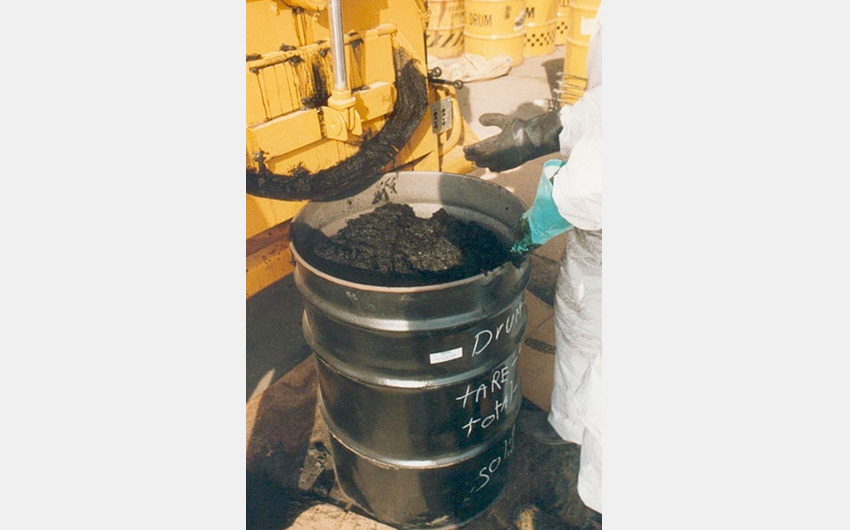

One cubic foot of sludge weighed 120 lbs. and the approximate percent, solids ranged from 74% to 78%.

Sludge Excavation

The sludge was excavated from the pond using a one cubic yard drag line bucket. When excavated, the material was similar in consistency to a chalk-like paste. When the slump test was performed, the material ranged from 4” to 10.”

The drag line bucket excavated the material and dumped directly into the top of the Maxcrete. The Maxcrete was modified to include a charge hopper 5’ wide by 10’ long positioned at the charge end of the mixer. The charge hopper was mounted directly to the top of the Maxcrete and included a steel grizzly with a 4” by 8” configuration. The grizzly would catch larger items including stumps, roots and other miscellaneous items.

The drag line bucket continuously fed sludge to the Maxcrete at a rate of 1 yard per 40 seconds while the Maxcrete mixed and discharged the material. Total product per hour was 120 tons/80 cubic yards per hour. Production was primarily limited by the capacity of the concrete pump and the loading time of the drag line operation.

The Cement Mixture

A grout mixture of cement was added directly into the Maxcrete. The cement was mixed and pumped into the Maxcrete to reduce the dusting caused by handling cement in dry form. The grout mixture was introduced into the Maxcrete at a rate of 170 lbs. dry cement to one cubic yard of sludge (approximately 5% cement to tailings ratio).

In addition, it was advantageous to increase the slump from 9.5” to 10”, thus requiring the introduction of water. Along with the 5% cement, water was added on demand based upon random slump testing and visual observation.

The Mixing

The cement grout mixture was added to the sludge inside the Maxcrete to increase the psi of the material. Thorough mixing was confirmed through both visual inspection and testing performed regularly on the output from the Maxcrete.

The Discharge

The Maxcrete fed the cement/sludge mixture to a 28 meter truck mounted boom pump. The Maxcrete was equipped with the optional discharge screw auger which provided a constant flow to meet the pump rate.

The discharge screw auger speed can be varied for 0 to 5 cubic yards per minute discharge rates and is bi-rotational.

The discharge screw auger allows the Maxcrete to be placed on grade while discharging into the hopper of the pump. This configuration provides a low profile for easy loading and visual inspection.

The Drop Hole

The boom pump then pumped the sludge into a drop hole. The drop holes were bored at various locations above the abandoned mine. The sludge then fell through the drop hole an additional 60 feet. The material did not release water upon being deposited in the underground mine.

The entire remediation process was mobile, allowing the contractor to move the Maxcrete and pump around the pond, minimizing the distance the drag line had to move.

THE RESULT

The final product provided a flow able fill to backfill various mining cavities. The project allowed the owner of the sediment pond to accomplish three tasks:

- The site owner was able to reclaim valuable real estate covered for over 60 years with calcium carbonate mining tailings.

- Rather than trucking the sludge offsite for disposal, the contractor was able to treat and dispose of it on-site.

- And, by pumping the sludge into the underground mine, the contractor was able to reduce exposure to liability for an abandoned mine.