Maxcrete Remixes Concrete for Chicago Harbor Lock Repair

Maxcrete Remixes Concrete for Chicago Harbor Lock Repair

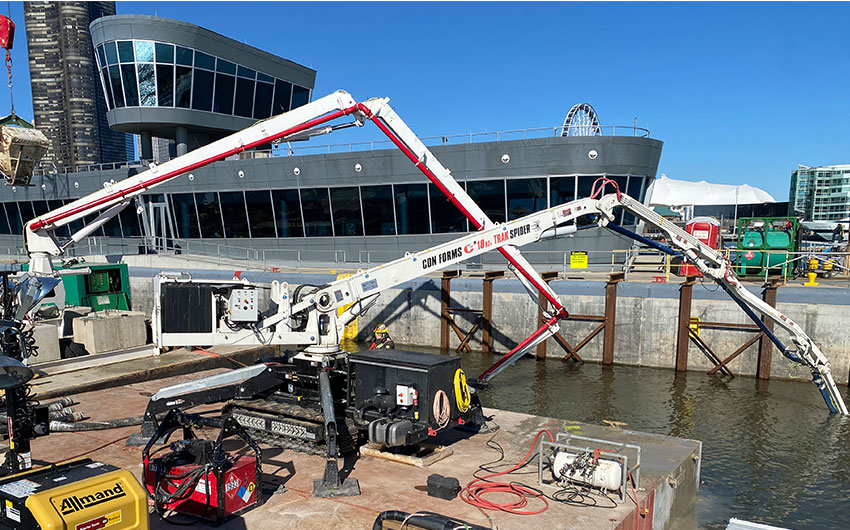

A look at the complete concrete system with the Chicago Skyline.

CONTRACTOR

LOCATION

Chicago Harbor, Chicago, Illinois, USA

APPLICATION

EQUIPMENT

SHARE:

OVERVIEW

The Chicago Harbor Lock, built in 1938 has seen considerable deterioration since initial construction. The U.S. Army Corps of Engineers (USACE) contracted J.F. Brennan to repair and the Lock Walls and Floors over multiple winter sessions (while the Lock remains open during the business Spring to Fall boating seasons).

The Lock services 75,000 vessels in a typical season allowing boats to travel from the lower elevation of the river to the Lake Michigan level.

THE EQUIPMENT

JF Brennan turned to Maxon to provide a remix surge hopper for the concrete placement of the Chicago Lock and Dam.

The Transport Barges each contain:

- (1) Maxon Maxcrete

- (2) Schwing Trailer Pumps

- (4) 3 yd3 Concrete Buckets

The Placing Barge contains:

- (1) CON FORMS Spider Boom

- (1) Pedestal Placing Boom

On Land:

- (2) Putzmeister Truck Mounted Telebelts

- Ozinga Ready Mix Trucks

Ready Mix trucks feed the Telebelts on land.

The Telebelts transferred material into 3 cubic yard buckets.

THE PROCESS

After removing damaged portions of the Lock floor and laying out new rebar mats, Brennan is in the process of resurfacing the Lock with tremie concrete. Concrete from Ozinga ready mix provider is brought to the jobsite on the waterfront in downtown Chicago. The concrete is then transferred to a transport barge via truck mounted conveyor (Telebelt) and placed into a set of 3 cubic yard laydown concrete buckets. The buckets are then barged out to the Lock and lifted and discharged into the Maxon 10 cubic yard Maxcrete on the placing barge. The Maxcrete allows the transport barge to be quickly offloaded and return for another load while the Maxcretes feeds two trailer mounted concrete pump. A diverter suspended over the two pump hoppers allows the concrete from the Maxcrete to be fed to either one or both pumps simultaneously. The Maxcrete allows Brennan the opportunity to remix the concrete and add Superplasticizer to arrive at the ideal placing consistency. The concrete pumps in turn feed one of two concrete booms (a CON FORMS Spider and a pedestal mounted boom) in placing the tremie concrete to the Lock floor 28’ below the surface. A set of two dive teams directed the tremie concrete for precise placement. Two major pours were performed this winter of roughly 250 yards each taking 36+ hours. Brennan is to return again in the coming winters to repair the walls in similar fashion.

Maxcretes accept concrete from the laydown buckets on transport barge.

The Spider and Pedestal Booms placed the concrete below the water surface.