About us

About Maxon

The History of Maxon Industries

The History of Maxon Industries

The name Maxon has been associated with the concrete industry for over 70 years. The evolution of Maxon equipment began in the 1930s when Glen Maxon Jr. went to work for T. L. Smith Company to develop more uniform and quicker concrete mixing with tilt mixers for the Tennessee Valley Authority. In the 1940’s he developed and was awarded a patent on the Plastigraff, a means of checking the slump inside a tilting central mix drum by measuring the resistance of concrete against the paddles inside the mixer. A series of lights outside the machine indicated the slump, or workability of the concrete. During the 1940s he formed his own company and designed the Dumpcrete, a non-agitated rear dump haul body. The patented unit utilized a high discharge point to allow the carrier to chute concrete. At the same time, he started Expressway Mixers, offering the first portable central mix plants. As an active member of ACI and ASCM, he submitted papers on concrete plants and concrete mixer blade designs in drums. After World War II he developed the idea of central mix concrete and hauling in non-agitating carriers. Air intrained concrete became the standard, which allowed concrete to be carried short distances without segregation. Glen Maxon Jr. was referred to as the “Father of Central Mix Concrete” because of his knowledge and development of mixing, hauling and placing central mix concrete.

Maxon Construction Company of Dayton and Tell City, IN was granted the license to manufacture the Dumpcrete by Glen Maxon Jr. Together they developed the Side Dump Maxon Spreader and a Side Dump Carrier, later referred to as the “Maxon Method of Concrete Paving”. Although some jobs were successful hauling non-agitated concrete, other types of concrete were not suitable for transport over long distances. Glen Maxon Jr. received the first patent for an open top agitated concrete carrier called the Agitor. The Agitor had a conical shaped shell to allow an agitator to turn inside and keep the concrete consistent.

A New Generation

After attending Massachusetts Institute of Technology and 2 years of service in the U.S. Army, Glen Maxon III joined his father to help build the first Agitor with S&M Manufacturing. The first 4 yard Agitor was sold to a concrete paver, C.F. Replogle in Circleville, OH. The 4 yard Agitor proved to be too small for mainline paving and in 1959 the first 8 yard Agitor was built. This machine went on to be the forerunner for interstate and airport paving. Many interstate projects throughout the U. S. utilized the 8 yard central mix plants with 8 yard Maxon Agitors carrying concrete to the paver.

After attending Massachusetts Institute of Technology and 2 years of service in the U.S. Army, Glen Maxon III joined his father to help build the first Agitor with S&M Manufacturing. The first 4 yard Agitor was sold to a concrete paver, C.F. Replogle in Circleville, OH. The 4 yard Agitor proved to be too small for mainline paving and in 1959 the first 8 yard Agitor was built. This machine went on to be the forerunner for interstate and airport paving. Many interstate projects throughout the U. S. utilized the 8 yard central mix plants with 8 yard Maxon Agitors carrying concrete to the paver.

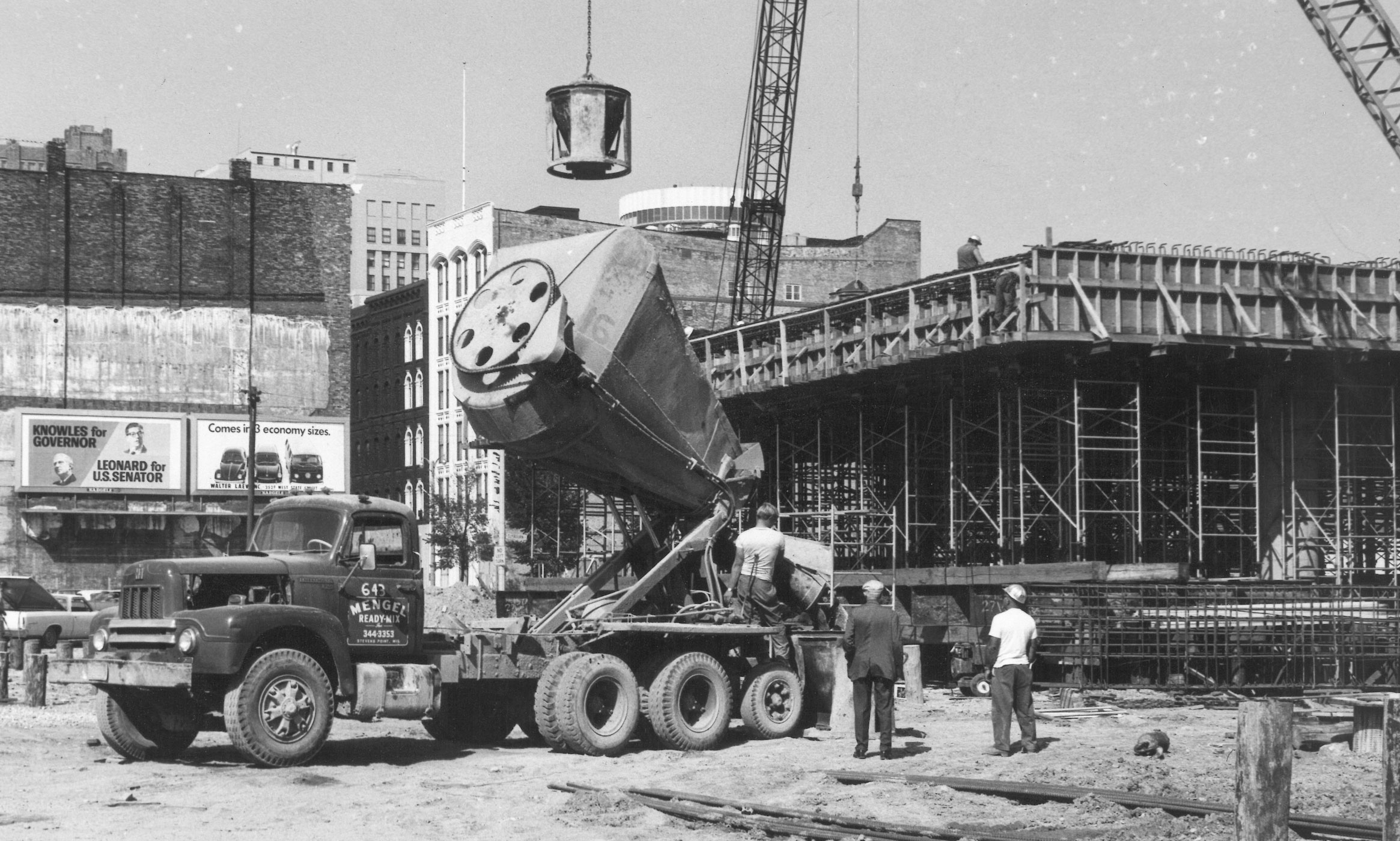

In the 1960’s, Glen Maxon Jr. and Glen Maxon III formed Maxon & Son. Included in their efforts were patents on several features for the Maxon Agitor and concrete belt placers. They also developed a unique, agitated concrete body called the 8 by 8. Having dimensions of 8 feet in all three directions, it could be mounted to dump either over the side or the end of the chassis. Used as a side dump carrier, the 8 by 8 was noted for it’s rapid discharge, 8 cubic yards in 10 seconds. Maxon & Son also developed a portable 4.5 cubic yard central mix drum. The patent included unique mixing blades and a narrow frame width, making it easily portable.

Maxon Industries is Formed

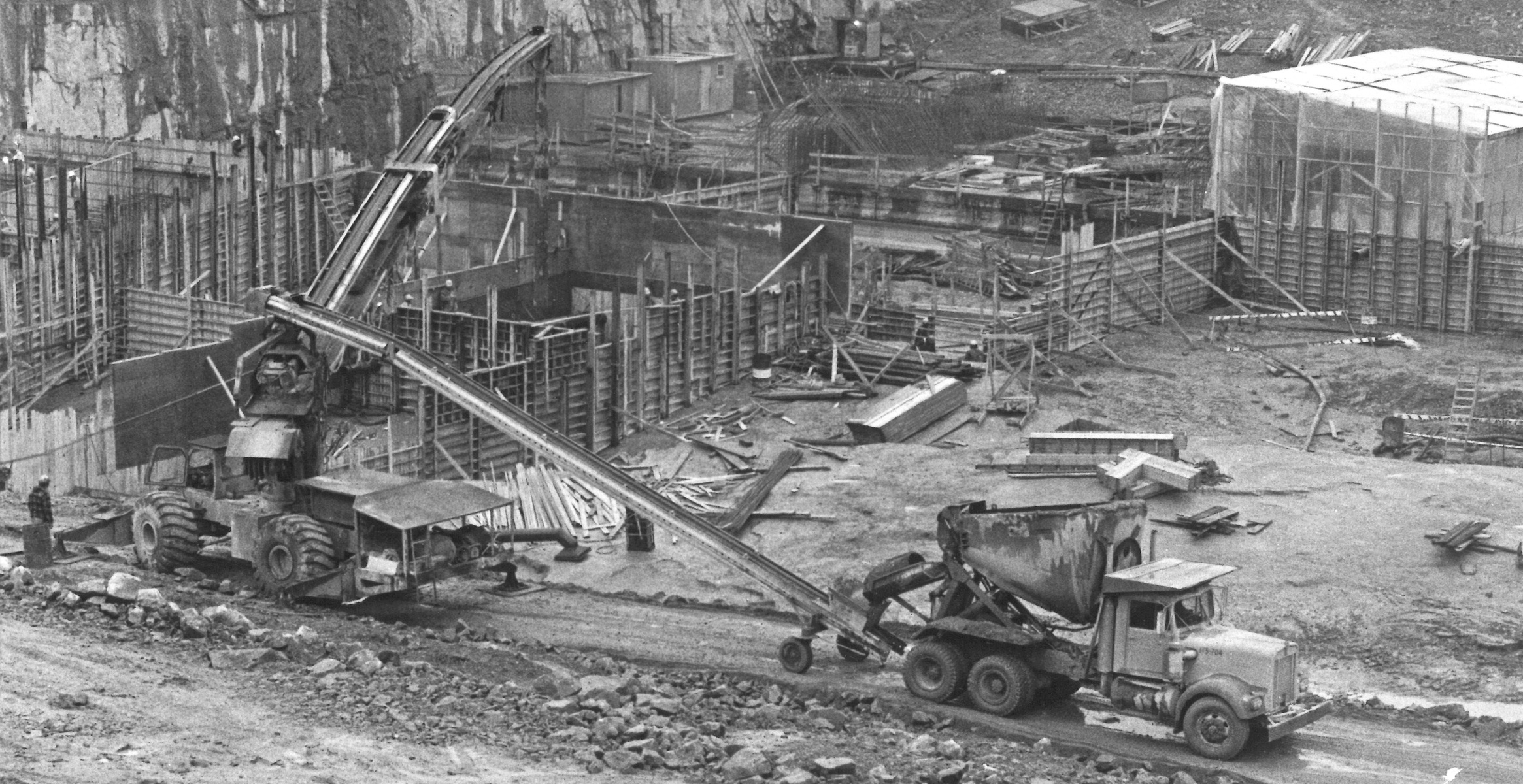

When Glen Maxon Jr. retired in 1972, Glen Maxon III formed his own company, Maxon Industries, Inc. Initial projects for Maxon included development of a special truck mounted concrete carrier with a 15′ belt conveyor for prestress concrete. In addition, several changes were made to the Agitor to make it work with low slump and mass aggregate concrete. In one of the last programs for the atomic power industry in the U.S., the Tennessee Valley Authority used 50 Maxon truck mounted Agitors to build 6 projects.

When Glen Maxon Jr. retired in 1972, Glen Maxon III formed his own company, Maxon Industries, Inc. Initial projects for Maxon included development of a special truck mounted concrete carrier with a 15′ belt conveyor for prestress concrete. In addition, several changes were made to the Agitor to make it work with low slump and mass aggregate concrete. In one of the last programs for the atomic power industry in the U.S., the Tennessee Valley Authority used 50 Maxon truck mounted Agitors to build 6 projects.

Maxon Industries went on to design larger Agitors including 10, 12 and 15 cubic yard units. Recent changes to the Agitor include: a wider gate opening; direct drive agitators; and a special agitator shaft to handle low slump and mass aggregate concretes. The new Agitor has been highly accepted by both concrete pavers and dam constructors because of it’s dramatic increase in performance over older models.

New Advances

New Advances

In the 1980’s Maxon Industries built the first Maxcrete, a low profile open top carrier for mine development work. The Maxcrete incorporates an open top body for easy loading, a large discharge gate for fast unloading and a full sweep paddle design for complete re-mixing or re-tempering of the concrete. The Maxcrete is built in 4.5 to 26 cubic yard capacities and is available skid mounted, rail mounted or for installation on rubber tired vehicles. New Maxcrete designs include trailer mounted units and low profile units to accept concrete not only from Agitors, but also transit mixers, Moran cars and dump trucks. Recent additions to the Maxcrete include feed and discharge screw conveyors, ideal for low profile transport and/or remix applications. In tunnel and mining applications, the Maxcrete acts as a surge hopper to discharge directly into a concrete pump while being re-loaded by Agitors on rail cars. Additional advances in the concrete transportation industry include the Maxon MaxSlide which allows a concrete carrier to dump to either side and the rear. This turntable style option for the concrete carrier eventually made the original Maxon Side Dumpcrete obsolete.

The Present

Today the company continues with a core focus on mixing, transporting and placing concrete. Bill Maxon represents the third generation to lead the company, and the fourth generation is already active in day to day operations.

With a focus on large civil projects around the world, Maxon has now placed concrete on six continents, and over 80 countries. Recent projects include the Central Subway and Purple Line Extensions in California, the East Side Access project in New York City, the $10 billion Site C Hydroelectric Power project in Fort Saint John, BC, Canada, the Nestor Kirchner and Jorge Cepernic Dams in Argentina, and the Polavaram Water project in India. Recently completed projects include the Panama Canal Expansion where 48 Agitors and 12 Surgecretes placed 5 million cubic meters of concrete, and the Mario Cuomo Bridge in New York where Maxon provided three (3) barge mounted systems to mix and place concrete on the Hudson River for all the foundation and structure work.

Coast to coast, and throughout the world, Maxon offers comprehensive engineered solutions to place concrete on the most difficult projects.