applications

Maxon equipment applications include; processing tailings from mining operation; paste treatment and backfill applications for underground hard rock mines; remediation of existing and closed mine tailing ponds; and tailing processing for coal fired power plants. Equipment includes single and twin shaft mixers, remixers and agitators for processing and placement of thickened tailings or paste. Maxon Maxcretes and Agimaxs are used extensively for accepting tailing slurry, mixing or blending with cement or flyash to create a paste or slurry, and continuously feeding to placing devices including concrete pumps, conveyors or directly to stock piles or landfill.

Mine Tailing Remediation

Most mining operations generate tailings when separating the valuable minerals from the excavated ore body. Historically, those tailings were discharged into ponds, impoundments, mine dumps, clum dumps, slime tailings, leach residue, tailings dams, or slickens. Here the tailings tend to leach water that will carry heavy metals or other contaminants.

Coal Power Plant

Coal–fired power plants currently fuel 37% of global electricity and create a number of waste streams including, overflow from floatation tanks to separate fine coal and the separation of unburned carbon from the bottom ash. Treatment solutions include dewatering of the tailings with belt presses and using paste thickener technology (addition of cement) and processing of underflow tailings as part of the floatation process.

In-Plant Installation

Maxon custom engineers and manufactures equipment to meet specific customer requirements for in-plant applications. Projects include mineral processing operations for mines, and treatment of waste streams generated from power plants.

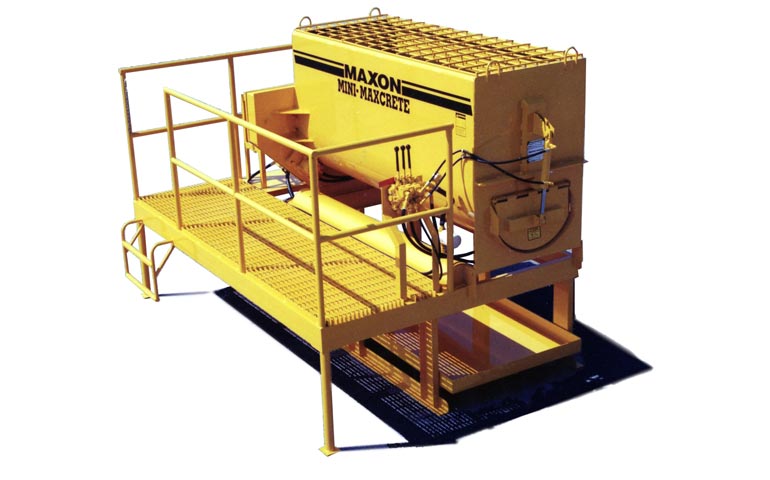

Mobile/Portable Equipment

For remediation of existing tailings ponds, Maxon offers a line of mobile or portable equipment. Waste material from tailings ponds are excavated by crane/bucket or excavator and fed directly to an open top Maxon Maxcrete, then mixed with a solidification agent (cement, fly ash, kiln dust, etc).