applications

Maxon is the industry leader in providing concrete construction equipment for major marine projects across the globe including the San Francisco Bay Bridge, Lake Mead Water Intake Tunnel and Mario Cuomo Bridge. Maxon Agitors and Maxcretes combine to offer customers a complete concrete transportation and placing solution when working on bridges, cofferdams, locks, channels, or footing and foundation work for underwater (tremie) concrete placement. Barge mounted Agitors are the perfect solution to transport concrete from shore to pour site, while the Maxon Maxcrete offers customers a remix surge hopper to feed concrete to boom pumps, trailer pumps, placing booms and concrete buckets.

Barge Transporters

Maxon barge mounted concrete transport systems include Agitors with diesel or electric power packs, platforms, conveyors and wash down systems. The open top Maxon Agitor, available with haul capacities up to 20 yd3 (15 m3), can be easily loaded from shore directly or with a concrete pump / conveyor.

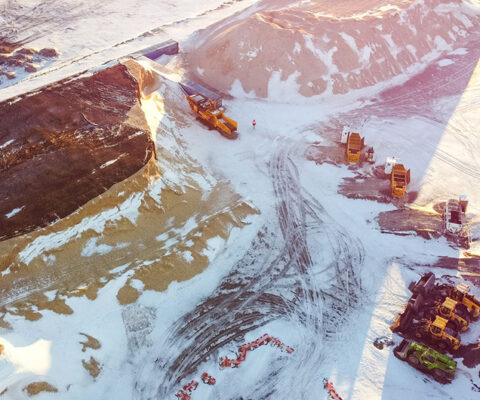

Offshore

Placing concrete for underwater/off-shore applications brings its own set of issues. The experts at Maxon have unique equipment solutions for under water tunnels, oil platforms, pilings and piers, docks, dams and other civil applications. From tremie pours to structural form pours in cofferdams, Maxon has the right equipment to meet your challenges.

Remix Surge Hoppers

To maximize production rates and ensure the best quality concrete, Marine contractors rely on the Maxon Maxcrete Remix Surge Hopper on the Placing Barge. The open top Maxcrete allows contractors to rapidly off load any concrete transporter (Agitor, ready mix truck, or bucket) and return, reducing cycle times.

Custom Solutions

Have a complicated pour or a mix design that’s hard to work with? Need a complete solution from shore to placement, or perhaps a short term rental of your concrete placing system? Maxon offers engineered solutions with experience from thousands of applications.

Barge Mounted Agitors

Traylor Massman Weeks utilized barge-mounted Maxon Agitors on the New Orleans area Hurrican and Storm Risk Reduction System. There were three barges with two 10 cu yd Agitors each. The Agitors were powered with an independent diesel power pack allowing them to agitate concrete while in transit for the 1+ mile trip to the placing site.