applications

Maxon offers a complete line of equipment to process, stabilize, solidify, and encapsulate a wide array of waste materials, economically and efficiently. The Maxon Maxcrete is an open top paddle / pugmill style mixer with a bi-rotational agitator shaft to ensure a quality mix. Units are available with either single or twin shaft agitators, in cubic capacities from 1 yd3 (.5m3) to 20 yds (16m3).

On-Site Solidification

Maxon offers skid and trailer mounted units for on-site processing and solidification of waste streams. With units up to 20 yd3. Maxon offers solutions that allow contractors to easily move the entire system from site to site, or around the project. Maxon’s full line of open top pugmill style mixers allow contractors to quickly mix liquid and semi-solids materials at contaminated sites with a solidification agent (cement, fly ash, or similar).

Waste Encapsulation

In addition to solutions for waste solidification (mixing waste with cement or fly ash to form a solid matrix similar to concrete to physically bind the waste) Maxon offers mixers/pugmills to encapsulate and stabilize waste streams as well. Stabilization is a process in which waste streams are mixed with reagants to create a chemical reaction transforming pollutants to less mobile/insoluble species, thus eliminating the potential for contaminated lechate from landfills.

Pharmaceutical Waste

Disposal of expired and unused pharmaceuticals is a worldwide public health issue. In remote locations, where “inexpensive” disposal occurs in uncontrolled landfills, pilfering and diversion occur for drug misuse and contaminated leachate (water that comes in contact with landfill waste) pollutes drinking water.

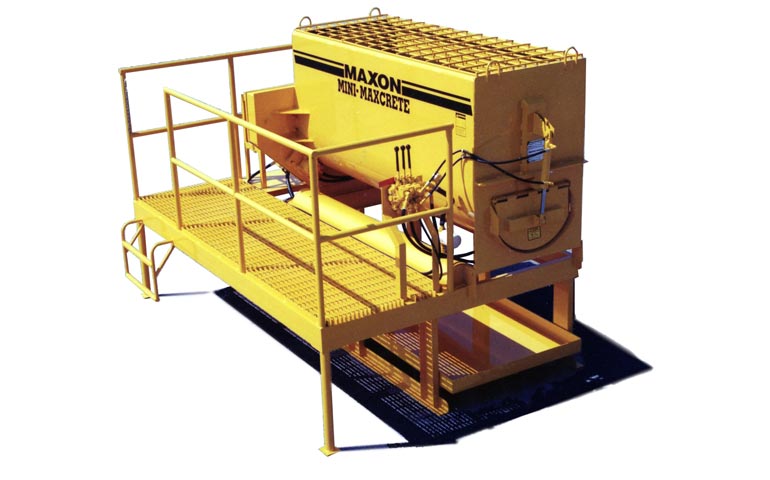

Fixed Installation

When industrial manufacturers and waste processing facilities are looking for complete waste handling systems to incorporate within their existing building footprint, they turn to the experts at Maxon. In-plant operation allows sludge and liquids to be pumped directly to the Maxon mixer, reducing material handling and storage issues.