Maxon Agitor for Self-Consolidating-Concrete

Maxon Agitor for Self-Consolidating Concrete

CONTRACTOR

LOCATION

Winchester, Virginia, USA

APPLICATION

EQUIPMENT

SHARE:

OVERVIEW

The Shockey Precast Group of Winchester, Virginia is a leading supplier of concrete precast panels, precast double “T”’s and related precast products to the heavy and civil construction market in the mid-Atlantic region. For decades, Shockey has supplied high profile state, federal and commercial projects with the highest quality precast elements.

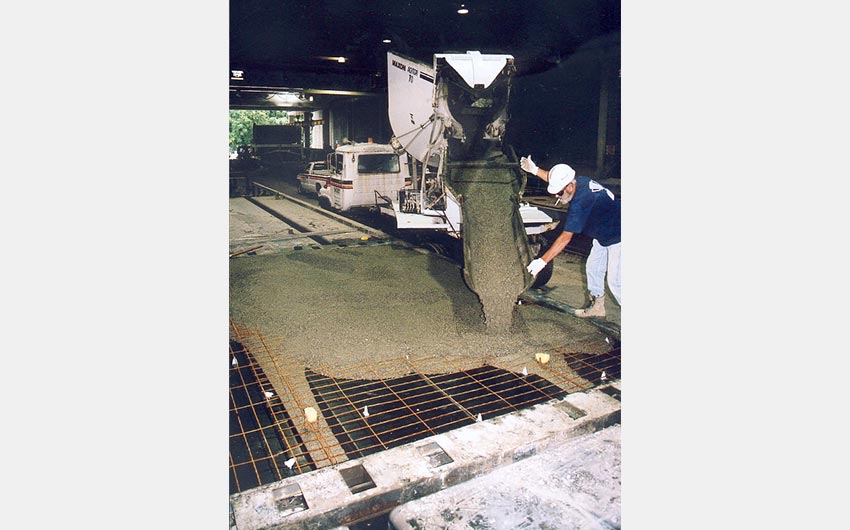

Crider & Shockey (Ready Mix Division) utilizes a 10 cubic yard central mix plant and transports the concrete to the various forms on their 80 acre site with either one of the seven Maxon Agitors or with one of their conventional ready-mix trucks. The Maxon Agitors have offered Crider several advantages:

- A higher discharge point (compared to ready mix trucks)

- A Max-Slide Frame which moves the discharge point closer to the forms

- Chute system to place concrete directly into higher and wider forms

Their Agitors include the Maxon Max-Slide system allowing the discharge end to the Agitor to swing 2 feet to either side of the truck, making it easier to place concrete at the furthest points within the form. (Conventional ready mix trucks often must place concrete into a bucket, which then places the concrete into the forms.)

THE CHALLENGE

With the recent advances in SCC, Self-Consolidating Concrete, Shockey turned to Grace Construction products to evaluate the possible introduction of SCC into their precast operations.“The SCC samples we have produced have been very encouraging,” states Tim Wells, Vice President, Shockey.

The SCC offers precast operations a number of advantages:

- Better flow ability within the forms reduces or eliminates the need for vibration

- Less vibration increases form life

- Better consolidation throughout the form produces a better quality product that requires no extra finishing after the forms are removed

“While the SCC may offer us a number of advantages, we found that we need to keep much tighter tolerances on the mix design during the evaluation process,” states Charles Cain, Area Manager/Plant Supervisor for Shockey. The new SCC mix design incorporates 4 different aggregate gradations with more fines than their old mix design. “The SCC mix we are testing is slightly more expensive, and can take a couple of extra minutes longer to mix, but we hope to recover those costs and more, in the placing, striping and finishing stages,” states Cain.

Additionally, Shockey has found that the SCC can be “tricky” to transport from the plant to the various placing sites around the yard. “We found that in testing and developing the best mix and procedures for our facility, that at times the SCC slump was inconsistent within a load and the air entrainment was slightly low,” comments John Kaulen, Quality Manager for Shockey. Shockey turned to Maxon to assist in resolving these issues.

Maxon proposed a new “SCC Agitator” to be installed into their current Agitors. Their standard Maxon Agitors included a bi-rotational, horizontal agitation shafts with seven knife blades which assist in keeping low slump concrete from segregating while in transit. The new SCC Agitator developed by Maxon has 10 paddles with additional surface area on each paddle providing considerably more agitation of the load. “The new SCC Agitator in the Maxon Agitor clearly allows our SCC admixture to perform better,” stated John Swart, district Manager for Grace Construction Products.

Bi-rational, horizontal agitation shafts for SCC.

THE RESULT

In testing, Grace found that an Agitor with the new SCC Agitator used in conjunction with the proper mix design resulted in consistent flow rates of 25- 27” with approximately 5% air. The new SCC Agitator continually mixes the SCC in the body, “folding” the materials, creating the best homogeneous mix with better air consistency.

“We are extremely happy with the responsiveness of Maxon. The Maxon Agitors have shown to be very valuable over the years in our precast operations. Now with the new SCC Agitators they work even better, allowing us to use the Agitors with either the old mix design or when testing the new SCC.”

-Charles Cain, Area Manager/Plant Supervisor for Shockey

Shockey continues to evaluate the advantages and possible introduction of SCC in their precast operations. With multiple forms and applications for precast elements, SCC may prove to be the best option for double “T’s”, where the old mix design may continue to be less expensive elsewhere. As explained by Cain, “while we continue to assess the addition of SCC to our precast operations, it’s good to see that our Agitors can deliver a quality product with either mix design.”